Why Apollo™ Disc-Kleen Filters

SAVE MONEY BY REDUCING FILTER SIZE

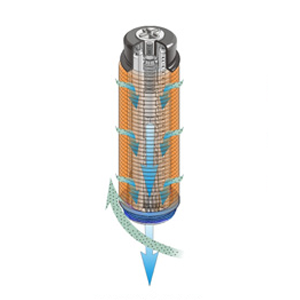

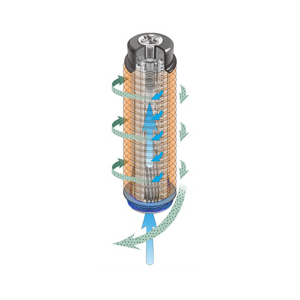

The Apollo features a longer filter element (spine) with larger discs (rings) producing a larger filtration area which accommodates a higher flow rate so the total number of filter units is reduced – lowering the filter cost.

SAVE MONEY BY REDUCING PUMP SIZE

Only 30 psi is required for backflushing reducing the need to oversize the pump for adequate flushing and it also reduces the need for a Pressure Sustaining Valve.

SAVE TIME & MONEY WHEN MOVING

The Apollo is lightweight with a small footprint making it portable and easy to move which is ideal for crop rotations and rental units in row crop applications.

SAVE MONEY ON MAINTENANCE

Made from high-density synthetic materials, it’s corrosion-proof not just corrosion resistant. Chemical injection upstream of the filter unit will not damage any filter components.