Product Advantages

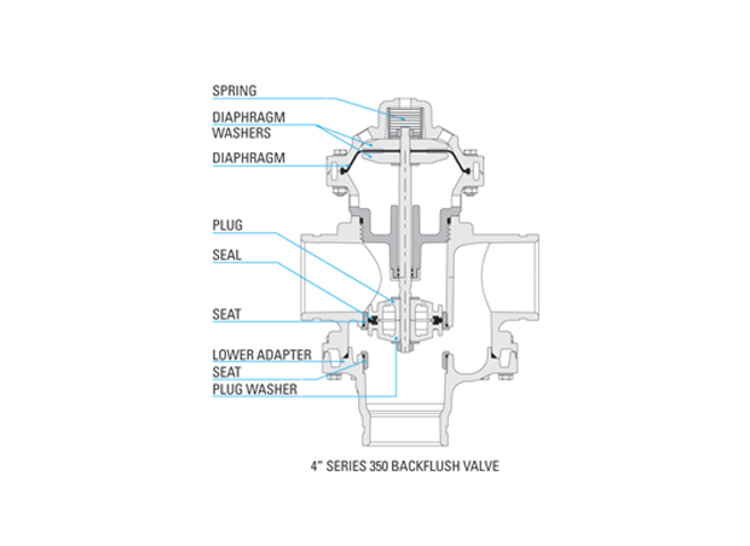

- 3-Way hydraulically operated diaphragm valves with low pressure loss.

- Double chambered design requires low actuation pressure for a wide application range.

- Dynamic sealing diaphragm seals at very low pressure and prevents seal friction and erosion.

- Highly durable reinforced plastic valve is chamical and cavitation resistant.

- T-configuration valve has a common outlet connected to the filter inlet and two other outlets - one to the water inlet manifold and the other to the drain manifold.

- Used with disc and sand media filters.

Applications

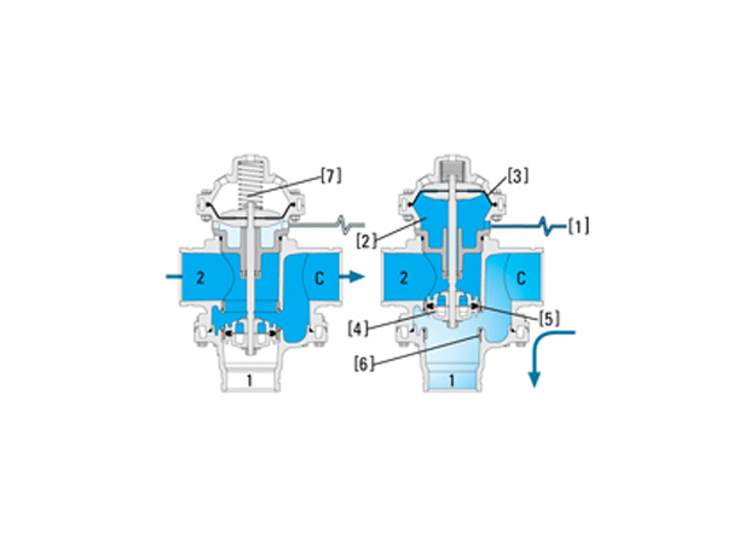

- A hydraulic command from the solenoid, which pressurizes the Lower Control Chamber, forces the diaphragm actuated Plug Assembly to move towards the Supply Port Seal, eventually sealing the valve drip tight.

- This allows water flow from the filter through the Drain Port Seal.

- Venting the upper control chamber causes the line pressure, together with the Spring force, to move the valve back to filtration mode.

Specifications

Series 350 Backflush Valve Specifications

- Operating Pressure: 10-145 psi

- Maximum Temperature: 150° F

- External Operating Pressure: 85%-100% of operating pressure

- Control Chamber Displacement Volume: 2″ – 0.03 gallons; 3″ – 0.09 gallons; 4″ – 0.15 gallons

- 2″ Series 350 Connections: Inlet – 2″ Grooved (Victaulic); Outlet – 2″ Threaded; Flush – 2″ Threaded

- 3″ Series 350 Connections: Inlet – 3″ Grooved (Victaulic); Outlet – 3″ Grooved (Victaulic); Flush – 2″ Threaded

- 4″ Series 350 Connections: Inlet – 4″ Grooved (Victaulic); Outlet – 4″ Threaded; Flush – 4″ Grooved (Victaulic) or 3″ Threaded