Product Advantages

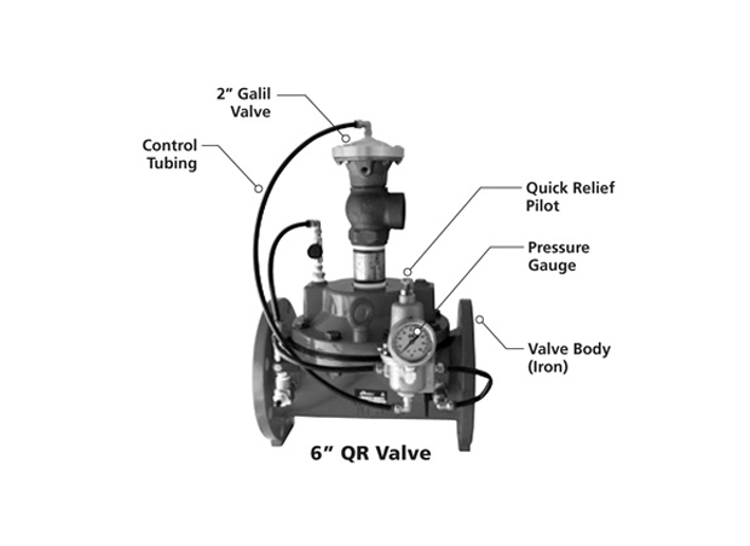

- Hydraulic valve with direct sealing diaphragm means longer functional life. No stem, shaft or bearings within the water passage.

- Easy installation and low maintenance.

Applications

Quick Relief (QR) Valves Technical

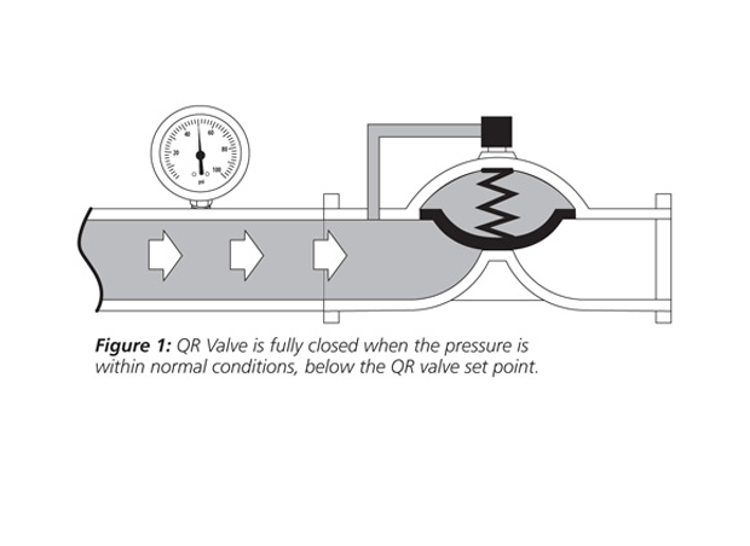

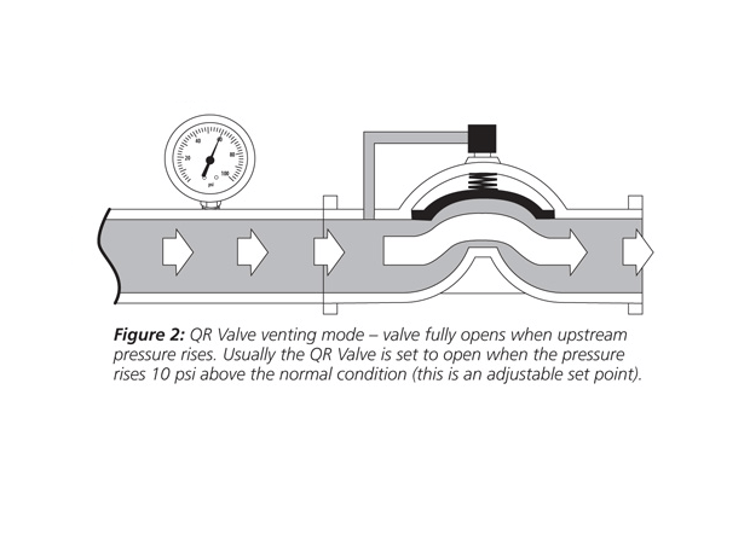

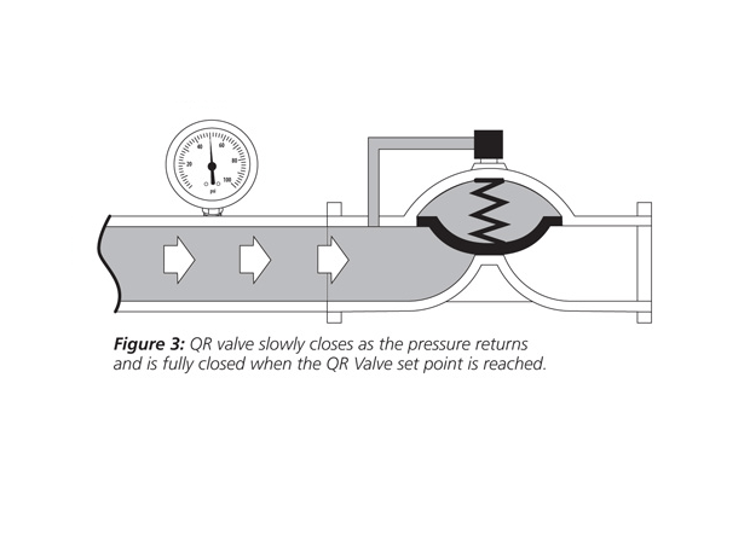

A Quick Relief (QR) Valve ships pre-assembled by Netafim USA following strict quality standards. The QR Valve consists of a basic valve, a quick relief pilot and a needle valve (some pilots come with an integral needle valve where the needle valve is inside the pilot); Valves 6” and larger use an additional 2” Galil valve so the chamber of the valve will vent quickly even if the valve is large.