Why Iron Valves

- Unique design allows a straight flow pattern with lowest friction loss in the industry.

- Superb hydraulic performance with low operating pressure.

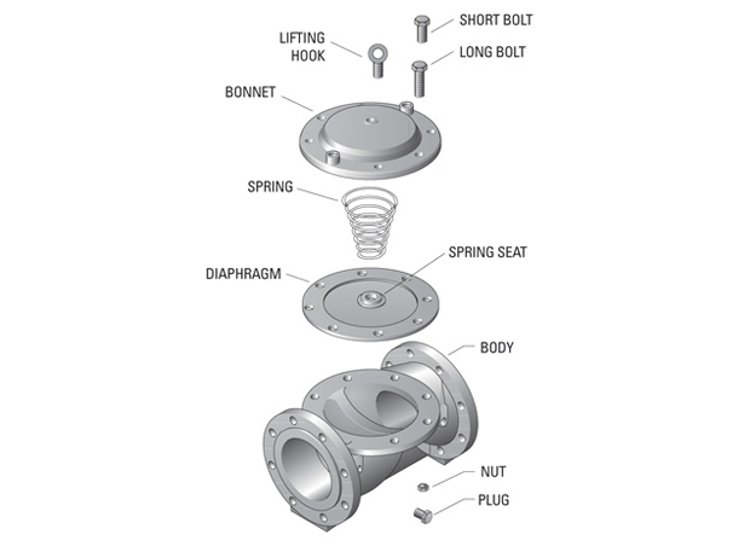

- Direct sealing diaphragm for positive opening and closing.

Iron Valves are available in a wide range of sizes and flow rates to cover most applications. The unique design allows a straight flow pattern with low friction loss. A direct sealing diaphragm, the valves only moving part, operates by pipeline or external pressure. Sizes range from 1″ to 24″ with a variety of control functions and connection options.

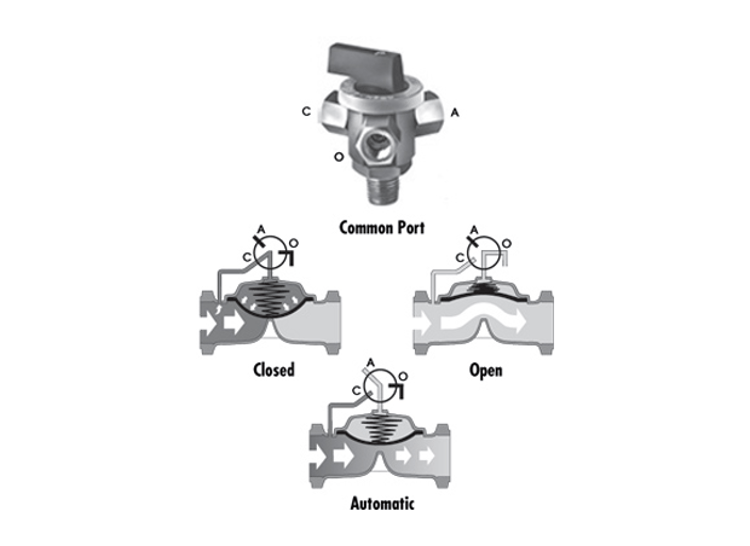

The basic valve can be operated manually through the use of a 3-way selector. Selector options and their functions include:

(C) CLOSED Upstream pressure or pressure from an external source is applied to the control chamber. Initiated by the spring, the diaphragm is pressed down to close the valve drip-tight.

(O) OPEN Relieving the water or air pressure to the atmosphere from the control chamber causes the valve to open.

(A) AUTOMATIC The automatic port of the 3-way selector is connected to a solenoid, hydraulic relay or pilot, which controls the valve. The common port of the 3-way selector connects the control chamber to either A, O, or C, depending on the direction the selector is pointed.

Contact a valve expert to learn which one suits your needs.