Cultivation Solutions

Leveraging our leadership in drip irrigation, Netafim is pleased to offer products and solutions for greenhouse commercial crop production. With precision irrigation products, precision nutrient injection and monitoring tools, you’ll get efficient use of water, fertilizers, and energy. You can maximize your investment by operating and monitoring schedules and system performance. We are committed to providing high quality, effective, reliable and durable solutions. Whether your operation is small or large, Netafim has the right products to deliver a uniform, top quality crop.

Small to Medium Containers

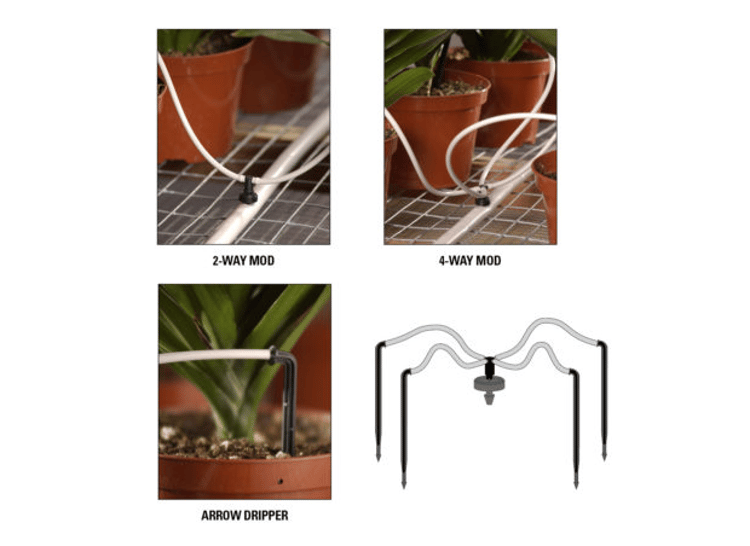

2-Way and 4-Way Multi-Outlet Dripper (MOD) Assemblies

For precise delivery of irrigation water and nutrients, regardless of the position or elevation of the growing area. Quick and simple installation and ideal for 0.25 to 25-gallon containers. One stake required for every 8” to all sides in soilless substrates.

This sample system layout can irrigate:

- 100 plants in 1 gallon or smaller containers, 1 stake per pot

- 50 plants in 3 gallon containers, 2 stakes per container (as shown in sample layout)

- 25 plants in 5 to 7 gallon containers, 4 stakes per container

- 25 or 16 plants in 10 to 25 gallon containers, 4 to 6 stakes per container depending on container diameter

Sample Layout for Small to Medium Size Containers with 4-Way Multi-Outlet Dripper (MOD) Assemblies

- 1 gallon or smaller containers, 1 stake per pot

- 3 gallon containers, 2 stakes per container (as shown in sample layout)

- 5 to 7 gallon containers, 4 stakes per container

- 10 to 25 gallon containers, 4 to 6 stakes per container depending on container diameter

Large Containers

Pressure Compensating (PC) Spray Stakes

For uniform water and nutrient distribution over a broader surface area and extremely effective in larger pots with loose, soilless media. Used for larger containers/pots over 25 gallons and/or with a wide diameter and grow bags. We recommend one spray stake for every 1.5 sq. ft. of container surface area. This sample system layout can irrigate:

- 50 large containers/pots with 15” to 18” diameters

- 25 large containers/pots with 20” to 36” diameters

- 15 large containers/pots with 28” to 32” diameters

Sample Layout for Large Containers with PC Spray Stakes

- 1 Spray Stake for pots with 15” to 18” diameters

- 2 Spray Stakes for pots with 20” to 36” diameters

- 3 Spray Stakes for pots with 28” to 32” diameters

Best Practices

The above shot volumes and run times are aimed at vegetative growth. When going from the vegetative stage to the generative stage, you may need to double the shot volume and double the time in between shots. This results in a slightly lower water content (WC) and higher EC in the substrate, which steers the plants in a generative direction. It is unknown how strong the effect is, but maintaining a root zone close to saturation with lower EC generally steers plants towards vegetative growth, so we want to do the best we can to steer towards reproductive growth when it is desired.

Always maintain the same volume applied per irrigation “shot” (say either 101.25 mL for veg or 202.50 mL for flower in a 6” cube) and add additional irrigation events to achieve the desired runoff % and EC content of the rockwool substrate. For the first week or two, you may only need to water once a day. However, it is perfectly normal to reach a point where your plants will need to be irrigated with these small shots upwards of 20 times per day, especially for outdoor and intense light greenhouse applications or very large plants in small cubes.

Begin with the first shot roughly 1-3 hours after sun-up (or lights-on) and stop irrigation events 1-3 hours before sun-down (or lights-off) to allow a bit of dry-back overnight and to prevent root rot (1 hour for vegetative stage, up to 3 hours for generative stage). The purpose of this ‘multi-pulse’ method is to maintain the root zone at the ideal balance of water content, oxygen and available nutrients at all times, preventing the plants from becoming stressed due to low water content, deoxygenation, or unbalanced nutrition/salt buildup in the root zone.

"The greenhouse responds to the weather to optimize plant growth, save water, and reduce the usage of pesticides."

Commercial Operations

10,000-43,500 Sq. Ft. Outdoor/Hoop House Kit

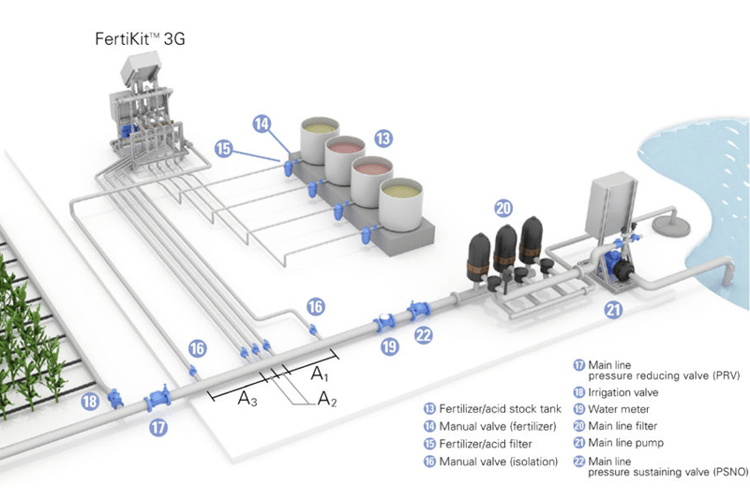

Kit Component #1: FertiKit 3G STS and Head Control

- Complete head control and fertigation solution

- Includes main system pump and filter

- Includes main controller capable of vast expansion

- Two fertilizer dosing channels (more available)

- One acid/alkali channel for pH regulation

- EC and pH sensors for automatic, precise injection and monitoring of fertilizers and pH control solution

- Optional Climate Station and remote access to controller is available through NMC Air

Kit Component #2: Zone Control

- Fast-acting Series 80 zone control valves

- Disc filters of various sizes, chosen based on flow rate of the largest zone

- Direct acting pressure regulators for each zone, chosen by flow rate

Kit Component #3: Water Application/Emission

Chose one of the three available options based on your specific method of growing.

Option 1: Raised or Trenched Soil Beds or Planted in Native Soil with Subsurface Drip Irrigation

- 17mm Techline® HCVXR Dripline, 0.33 GPH with 12” emitter spacing

- Barbed 17mm shut-off/flush valves

- Techline HCVXR has several features that prevent root intrusion during intentional water stress (e.g. promoting root growth in young plants)

Option 2: Hydroponic, using Rockwool, Coco Coir, Slabs or Small Containers

- 17mm (0.560” inside diameter) UV Bright White Polyethylene PE tubing

- CNL Pressure Compensating Barbed Emitters, 0.3 GPH (1.2 L/H) pre-assembled with 12” to 60” of white micro-tubing and angle barb stakes

- Barbed 17mm shut-off/flush valves

Option 3: Larger Containers with Greater than 1.5 Sq. Ft. Surface Area on Top, or Hydroton

- 3/4” (0.820” inside diameter) UV Bright White Polyethylene PE tubing

- Pre-assembled Pressure Compensating (PC) Spray StakeAssemblies, double spray pattern

- Barbed 3/4” shut-off/flush valves

- Distributes water over a larger surface area ensuring even wetting in large containers

Commercial Indoor Operations – 10,000+ Sq. Ft

Kit Component #1: NetaFlex 3G and Head Control

- Complete head control and fertigation solution

- Includes main system pump (filling pump or municipal supply of equal flow rate required)

- Includes main controller capable of vast expansion

- Up to 5 fertilizer dosing channels (more available)

- One acid/alkali channel for pH regulation

- Two each EC and pH sensors for automatic adjustment of injection rates and the most precise/accurate injection and monitoring available

- 10 fertigation recipes – with recipe selection for each zone valve

- Optional Climate Station and remote access to controller is available through NMC Air

Kit Component #2: Zone Control

- Fast-acting Series 80 zone control valves

- Disc filters of various sizes, chosen based on flow rate of the largest zone

- Direct acting pressure regulators for each zone, chosen by flow rate

Kit Component #3: Water Application/Emission

Chose one of the three available options based on your specific method of growing.

Option 1: Hydroponic, Using Rockwool, Coco Coir,

Slabs or Small Containers

- 17mm (0.560” inside diameter)

UV Bright White Polyethylene PE tubing - CNL Pressure Compensating Barbed Emitters, 0.3 GPH (1.2 L/H) pre-assembled with 12” to 60” of white micro-tubing and angle barb stakes

- Barbed 17mm shut-off/flush valves

Option 2: Larger Containers with Greater than 1.5 Sq. Ft. Surface Area on Top

- 3/4” (0.820” inside diameter) UV Bright White Polyethylene PE tubing

- Pre-assembled Pressure Compensating (PC) Spray Stake assemblies, double spray pattern

- Barbed 3/4”shut-off/flush valves

- Distributes water over a larger surface area ensuring even wetting in large containers

Option 3: Containers up to 25 Gallons, Closely Spaced Pots/Cubes

- 17mm (0.560” inside diameter) UV Bright White Polyethylene PE tubing

- CNL Pressure Compensating Barbed Emitters, 1.0 GPH (4 L/H) with nipple outlet

- Pre-assembled 4-Way Multi-Outlet Dripper (MOD) Assemblies with 4 lengths of 8” to 48” tubing and angle arrow dripper stakes

- Barbed 17mm shut-off/flush valves

Open Field

System Head

- FertiKit 3G SP NPT for precise, automated injection of multiple fertilizers at high mainline flow rates

- NMC Pro Controller and NMC Air – comprehensive farm automation and management solutions

- Various climate and soil sensors to monitor and adjust irrigation and fertilizer application

- Full line of hydraulic control valves, 3/4” to 12” sizes and 0.1 to 6,000 GPM

- Disc, screen and media filters (manual or automatic self-cleaning) and hydrocyclones for water with heavy sand content

- Water Meters from 1” to 12” sizes and 0.25 to 5,500 GPM flow ranges

- Air/vacuum relief and continuous acting combination air release vents

- FlexNet™ flexible, durable main/submain pipe with pre-installed 1/2” female threaded (FTP) outlets at various spacings for simple and efficient rollout and retrieval (if desired) – it can also be buried as a permanent submain

Option 1: Techline® HCVXR Dripline

- Pressure compensating emitter with Cupron® copper oxide, high check valve, CNL feature, 15 year limited warranty on root intrusion, 10 year warranty against stress cracks in full sunlight

Option 2: UniRam™ Anti-Siphon Dripline

- Pressure compensating emitter ensures uniform application of water and nutrients with the industry’s widest flow path and highest clog resistance and UV protection with 10 year warranty against stress cracks in full sunlight

Option 3: DripNet™ PC Thinwall Dripline

- Wide regulation pressure range, ideal for undulating terrain and large fields with long rows (up to 50% longer when compared to turbulent drip tape, 2 year warranty against defects

- Other types of thinwall driplines with non-pressure compensating emitters are available

Dosing

The most effective way to increase a crop’s yield and quality is by feeding the plant according to its specific, ever-changing needs. This means delivering the right amount of nutrients and water at the right time. Giving growers precise control over nutrient and water delivery, Netafim’s Nutrigation™ process is comprised of three stages:

- Dissolving solid fertilizers

- Mixing and distributing dissolved nutrients according to the desired dosing rates

- Delivering the precise quantity of nutrients to the plant’s root zone

For growers to carry out Nutrigation effectively, they require a full range of automated precision dosing systems. Netafim offers a comprehensive array of dosing systems to meet the specific needs of every grower. Leveraging decades of agronomic know-how and in-field deployment experience, we offer a world-leading portfolio of dosing systems including NetaFlex 3G and FertiKit 3G which are:

- Field proven, easy to install and operate

- Suitable for a variety of geographic and climatic conditions

- Easily integrated with Netafim control and monitoring systems

- Scalable to a wide range of irrigation system flow capacities

Need help finding the best solution?

Contact our Greenhouse experts to learn which solution is suited for your needs.